How To Pair a Recirculating Chiller with a Rotary Evaporator

by Mark Diener, Sr. Product Manager & Application Scientist/Chemist

image courtesy of Across International, Inc.

What role does a recirculating chiller/cooler play in rotary evaporation? How can you find the best recirculating chiller for your rotary evaporator? Let’s find out. In this article, we’ll cover the ins and outs of pairing a chiller with a rotary evaporator. We’ll also explore how temperature control plays a role in the condensation and distillation process and some of the technical specifications you’ll want to consider to ensure a smooth, safe, and reliable operation.

Introduction to Recirculating Chillers for Rotary Evaporators & Distillation

Since their invention in 1950, rotary evaporators, also known as rotovaps or rotavaps, have become ubiquitous and necessary devices in laboratories. Their design facilitates safe and efficient distillation for a wide range of solvents.

Temperature control plays a crucial role in the operation of the rotary evaporator. The rotary evaporator’s heating bath warms the solution to effect solvent vaporization. The vapors condense on the chilled condenser coils completing the contained distillation process. It’s similar to what happens when you place a metal pot with a glass lid on your stove. Let’s say there’s soup in that pot. You can see the soup boiling and observe how the vapors condense on the cooler glass lid. The top is cooled by the surrounding room temperature, usually somewhere around 20°C, whereas the vapor temperature is around 100°C. The stove scenario is similar to what happens with rotary evaporation.

Temperature Guidelines for Chillers & Rotary Evaporators

The most efficient conditions employ what is known as the 20-degree rule. Following the guidelines of the 20-degree rule, you’ll want to have a 20°C difference between the bath temperature, vapor temperature, and condenser temperature. For example, set the bath temperature to 50°C, adjust the vacuum setting for the solvent to yield a 30°C solvent vapor temperature, and operate the condenser(s) at 10°C. As you can see, the solvent vapor temperature is 20 degrees lower than the bath temperature, and the condenser temperature is 20 degrees lower than the vapor temperature.

A recirculating chiller or cooler ensures a consistent condenser temperature and eliminates seasonal temperature fluctuations that may occur when using tap water. A recirculating chiller provides an efficient, environmentally-friendly alternative to cooling with tap water, helping conserve water usage.

Recirculating chillers generally have the most cooling power at 20°C or higher. Operation of a rotary evaporator condenser at lower temperatures requires insight into the chiller capacity at lower temperatures. If the rotary evaporator will distill a range of solvents, it is best to size the chiller for the solvent requiring the lowest condenser temperature.

What to Consider When Sizing a Recirculating Chiller for a Rotary Evaporator

To calculate the necessary cooling capacity and the appropriate chiller, you’ll need to consider three factors related to a particular solvent.

1. Vapor temperature

2. Desired evaporation rate

3. Condenser temperature

JULABO can calculate the required chiller capacity for you based on these three factors. Reach out to your JULABO rep, and they’ll be happy to do the math for you.

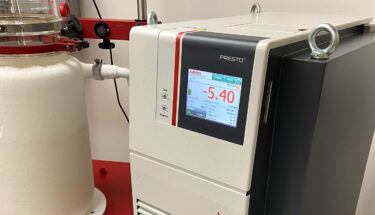

Chillers that are Ideal for Rotary Evaporators

Chillers for rotary evaporators come in a variety of sizes. Here are some ideal recirculating chillers for rotary evaporation based on vessel size.

Benchtop Units (to 5L): F250, FL601, F1000, FL1201

20L Units: FL2503, FL4003

50L Units: FL11006, FL20006

The JULABO recirculating chillers that start with “FL” offer proportional cooling. Proportional cooling enhances energy efficiency by adjusting the cooling power based on the external load. Some of the larger FL units provide a 3 and 6 bar pump that includes an internal by-pass for pressure adjustment. An analog pressure gauge on the front of the chiller displays circuit pressure. This allows you to adjust the pressure as needed and helps safeguard the rotary evaporator’s expensive glass condenser.

Key Takeaway on Sizing & Selecting a Chiller for Rotary Evaporation

“The lower the desired condenser temperature, the more cooling capacity you’ll need from your recirculating chiller.”

Indicators that You Don’t Have Enough Cooling Capacity

If the chiller temperature increases from the setpoint during operation this indicates that the cooling load exceeds the recirculating chiller’s cooling capacity. Inadequate cooling could result in solvent vapor exiting the rotary evaporator into the vacuum pump, potentially damaging the pump in the process. Solvent vapors escaping into the atmosphere could create regulatory problems if you’re using a solvent such as food-grade ethanol that requires careful logging of volume tracking.

Using One Recirculating Chiller for Multiple Rotary Evaporators

A single chiller can operate multiple rotary evaporators. In this case, a few rotary evaporators are daisy-chained together, and a single chiller cools down the circulating water. Note: you’ll need to be sure you have sufficient cooling capacity for each solvent and process if you’re using different solvents or have different condenser temperatures, vapor temperatures, or desired evaporation rates.

Conclusion & Next Steps

A recirculating chiller provides multiple benefits for your condensation and distillation processes. Whether you’re looking to purify, concentrate, crystallize, evaporate, or dry your samples, a rotary evaporator paired with recirculating chillers can streamline your process.

JULABO USA has chiller solutions with cooling power from 250 W to 20 kW and larger and temperature ranges from -25°C to +40°C. Our recirculating chillers can be used on rotary evaporators from one liter to 100 liters. To find the perfect recirculating chiller for all your condensing applications, get in touch with your dedicated JULABO USA account manager, who can help you with sizing and other factors. Or, shop our range of recirculating chillers.