Enhancing Reactor Temperature Control: A Vital Component in R&D, Process Development, and Optimization

Authored by: Dr. Dirk Frese, VP of Sales, Marketing & Service

Reactor temperature control plays a pivotal role in numerous scientific and industrial processes, particularly in research and development (R&D), process development, and optimization. Precise temperature management is essential for achieving desired reaction kinetics, product yields, and process efficiency. In this blog post, we describe the significance of reactor temperature control in these areas and investigate strategies for optimizing this critical parameter.

The Importance of Reactor Temperature Control in R&D:

In the field of research and development, reactor temperature control is predominant for exploring new reactions, synthesizing novel compounds, and analyzing reaction mechanisms. Accurate temperature control enables researchers to manipulate reaction rates, selectivity, and product distributions, facilitating the discovery and optimization of chemical processes.

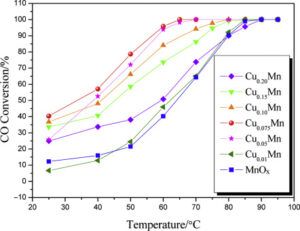

Moreover, in the field of catalysis and materials science, precise temperature control is essential for studying the thermodynamics and kinetics of reactions occurring on catalyst surfaces. Slightest variations in temperature can already significantly influence catalyst activity, selectivity, and stability, thereby impacting the development of efficient catalyst materials for various applications.

Example of a catalytic conversion yield influenced by temperature variations:

(Image source: https://images.app.goo.gl/CXhGPHdEK5kHjEQM6)

Process Development and Optimization:

In industrial settings, reactor temperature control is instrumental in process development and optimization. In pharmaceuticals, petrochemicals, or specialty chemicals, maintaining narrow temperature tolerances is crucial to ensure reproducibility, product quality, and yield consistency.

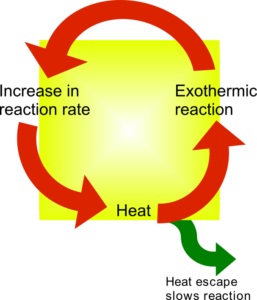

During process development, accurate temperature control allows engineers to identify optimal reaction conditions, such as temperature-pressure regimes, residence times, and heat transfer rates, leading to improved process efficiency and resource utilization. Moreover, precise temperature monitoring facilitates the detection of potential safety hazards, enabling interventions to prevent runaway reactions or thermal hazards.

Schematic diagram of a runaway reaction being controlled by heat removal:

(Image source: Wikipedia 2024; https://images.app.goo.gl/7ESnNqCpa58DagKU8)

Optimization of reactor temperature profiles is also central for enhancing energy efficiency and reducing environmental impact. By implementing advanced temperature control strategies, such as cascade control, model predictive control, and adaptive control algorithms, process engineers can minimize energy consumption, mitigate thermal losses, and optimize overall process performance.

Strategies for Enhancing Reactor Temperature Control:

Several strategies can be employed to enhance reactor temperature control in R&D, process development, and optimization:

Use of Advanced Temperature Sensors: Implementing high-precision temperature sensors, such as thermocouples, resistance temperature detectors (RTDs) like JULABO’s PT100 sensors available for many circulators, or infrared thermometers, enables accurate monitoring and feedback control of reactor temperatures.

Image showing a PT100 probe attached to a JULABO circulator:

The use of thermocouples of J, K and T types (ranges: -190°C-1200°C; -180°C-1350°C; -190°C-400°C), is sometimes favored over PT100s due to their smaller size. A converter box can be sourced from JULABO Thermocouple Converter Box (TCCB) to integrate them into the installation setup. Software packages like JULABO EasyTEMP® offer the ability to remotely control various JULABO circulators and display as well as analyze complex temperature profiles.

EasyTemp® Pro Screen and Package. Photo JULABO GmbH:

Adoption of PID Control Strategies: Proportional-Integral-Derivative (PID) control algorithms offer robust and versatile temperature control capabilities, allowing for fine-tuning of temperature setpoints, response times, and stability, which can be achieved by employing JULABO circulators of the Magio® and Presto® range or the Forte heaters (HT30 and HT60) as well as cryo-compact circulators CF31 and CF41. All of which have a self-tune function optimizing the PID controls without the necessity for the operator to manually tune each one of the PID parameters.

Integration of Thermal Management Systems: Incorporating efficient heat transfer systems, such as jacketed reactors, heat exchangers, or circulation loops, facilitates precise temperature regulation and uniform heat distribution within the reactor vessel.

JULABO Presto® A80 connected to a jacketed glass reactor.

Utilization of Advanced Control Algorithms: Adaptive control, model predictive control (MPC), or fuzzy logic control, enhances the dynamic response and disturbance rejection capabilities of reactor temperature control systems. This is especially helpful in complex and nonlinear processes. JULABO circulators are employed in all of the above-mentioned control types by making use of their PIDs.

Conclusion:

In conclusion, reactor temperature control is a critical parameter in R&D, process development, and optimization across various industries. Precise temperature control allows for exploring new reactions, developing efficient processes, and to optimize process efficiencies.