Cannabis Workflows, Part II: Solvents | Ethanol, King Of Classic

In our last post, we touched on the cultural and market shifts shaking up the cannabis industry – slash society at large – and how easy it is to get caught up in that dizzying whirlwind of “trendy tricks” and misinformation if you don’t ground yourself in the time-honored scientific basics. Extraction, distillation, vacuum distillation. Humans have been calling on these methods to separate and isolate desirables from undesirables since ancient times. So today, let’s dig into the cannabis solvents that make those processes possible.

Solvents, solvents, solvents.

After gathering the plant material, you need something to draw out the desirable components – mainly cannabinoids (CBD/THC), but some want those terpenes for aroma/flavor, too. This is where you’ve got lots of options. There is certainly no dearth of creativity when it comes to solvents for cannabis extraction and distillation. Do a quick Google search and you’ll find tons of solvent reviews, not to mention a handful of creative combinations and methods invented by very dedicated “garage scientists.” (Seriously, some of these guys and gals really know their chemistry, and the rigs they’ve MacGyvered are truly impressive.)

A handful of solvents work just fine, some not so great, some better than others… and, hey, three cheers for innovation, right? But if you want a reliable extraction process, there are three cannabis solvents that top pretty much every experienced extractor’s list.

We’ll hit on the first one today, and the other two in upcoming blog posts.

C2H5OH: Safe, effective, classic.

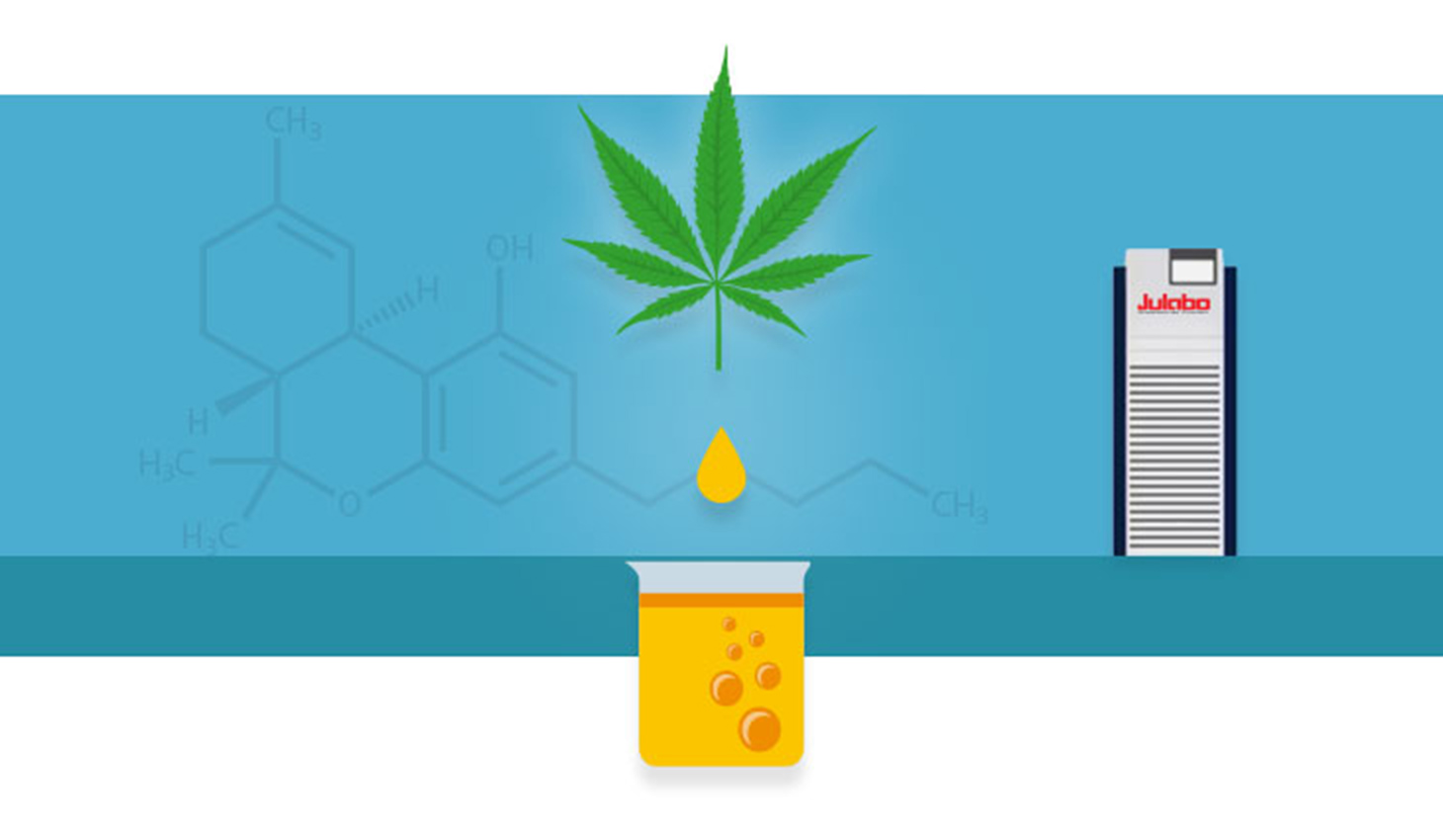

Some would argue that ethanol [C2H5OH] deserves the “universal solvent” title even more than our good friend H2O. This is because ethanol can dissolve both polar (hydrophilic) and nonpolar (hydrophobic/lipophilic) substances. It’s pretty much a solvent that invites everyone to the party. Very inclusive, that ethanol molecule is.

- Ethanol’s polar hydroxyl [OH] group – with oxygen’s high electronegativity allowing hydrogen bonding to take place with other molecules – will dissolve hydrophilic (water-loving) compounds like chlorophyll, pigments and tannins.

- Ethanol’s nonpolar ethyl [C2H5] group, a.k.a. its “hydrocarbon tail,” works with the hydrophobic (water-fearing) components like plant waxes/lipids, oils, cannabinoids, terpenes (aroma/flavor) and any other substance (except for plant fiber) that is present inside or on the outside of the plant. (And, of course, it’s these cannabinoids/terps we’re after.)

STEP ONE: Extract the desirables.

Now, a lot of people like using ethanol for cannabis extraction because

1) it doesn’t require high pressure like the other two popular solvents (supercritical CO2 and butane, which we’ll talk more about later) and is therefore safer, and

2) it produces a full-spectrum concentrate*. So, not only are you drawing out the big-name cannabinoids (CBD/THC) and terps, but you’re also getting the components that are present in much smaller concentrations – some of which haven’t been studied or even discovered yet, but could possibly play into the interactive synergy between marijuana compounds. This has been coined the entourage effect**, and many strongly believe that it’s this holistic (“full-spectrum”) interplay between plant parts that contributes to an enhanced therapeutic experience.

* This is if you’re using the “full-extract” method with hot/warm ethanol. Doing a “quick wash” with cold ethanol is a whole other ballgame because, due to shorter extraction time and lower (freezing) temperatures, the solvent won’t pick up nearly as many compounds. Extraction is a double-edged sword – the longer and more aggressive the process, the more both desirable and undesirable compounds will make it into the extract. So, a less intense extraction will get you a weaker concentrate, but you won’t need a hefty distillation process to isolate/refine the product. A longer and stronger extraction, on the other hand, calls for a longer, stronger distillation. Hence, “double-edged sword.”Check out this article on Culinary Solvent for a comparison between the “full extract cannabis oil” (FECO) and “quick wash with ethanol” (QWET) methods.

** The entourage effect has been getting a lot of attention lately, and for good reason. Very interesting stuff. Leafly has a fantastic read on the entourage effect and whole-plant medicine, including a great graphic of cannabinoids and terpenes with their individual and synergistic properties and benefits. Definitely check it out if you have the time and interest. (I did, and I’m certainly better for it.)

Temperature control units for EtOH extraction: PRESTO Temperature Control Systems and Refrigerated Circulators.

STEP TWO: Winterize the concentrate.

After extraction, you’ll need to winterize the concentrate to remove those unwanted lipids/waxes that the C2H5 ethyl group (nonpolar hydrocarbon tail) picked up. You do this by first dissolving the extract in some additional warm ethanol, and then cooling the solution to a temperature that’s low enough to precipitate (solidify) and filter off the undesirable fats.

Temperature control units for Winterization: PRESTO Temperature Control Systems and Refrigerated Circulators.

STEP THREE: Distill the concentrate.

Remember, our end game here is solvent-free extract oil. You do this through distillation (“purging”), the evaporation of solvents. Ethanol boils off at about 78°C at atmospheric pressure. If you pull a full vacuum (assuming you can pull -28.5”Hg), it reduces ethanol’s boiling point to 12.8°C, which is well below room temperature. These vacuum conditions safeguard against product degradation due to a significant reduction in heat exposure (thermal decomposition) and oxygen exposure (oxidation). You can use a rotary evaporator (roto-vap) or vacuum distillation apparatus to remove/reclaim the ethanol, yielding solvent-free extract oil. (You can also accomplish this by heating your solution in a hot water bath, but you won’t be able to reclaim the evaporated ethanol.)

Chillers for Distillation: Recirculating Chillers and Industrial Chillers.

Note: If you’re extracting with cryogenic ethanol (around -70°C) instead of warm ethanol, the winterization step is included. So, after extracting the desirable oils from the plant matter, you can go right to filtering (using something like activated carbon to remove whatever chlorophyll and other pigments that made it through) and removing/reclaiming the ethanol via distillation. However, since this is a frozen extraction, and temperature plays such a vital role in solvency, not as many components (desirable nor undesirable) will be drawn out of the cannabis.

So, to recap:

Because ethanol has both polar and nonpolar parts (and therefore dissolves both hydrophilic and hydrophobic molecules), and it doesn’t require a high-pressure extraction, it’s considered (by most) to be the safest and most effective cannabis solvent in the game. That being said, it’s certainly not the only option. Stay tuned for our next post, where we’ll continue our discussion on cannabis workflows with a look at two other popular solvents: supercritical CO2 and butane.

Can’t wait until the next Cannabis blog? Get the whole kit and caboodle by downloading our complete cannabis workflow whitepaper: The Cannabis Workflow and the Importance of Temperature Control.

Download The Weedpaper!