Croptober is Coming, Time to Concentrate

Croptober is coming. That means it’s the official harvest season for outdoor-grown cannabis. It won’t be long before a brand-new crop of sun-grown cannabis hits the market.

With Croptober on its way, it’s a good time for extraction artists, processing facilities and MIPs (marijuana-infused product) manufacturers to prepare.

What Croptober Means for Processors

In the coming months, the influx of outdoor-grown cannabis will affect almost every sector of the cannabis industry, including retailers, consumers, investors, and processors. Some of the cannabis will be cut, trimmed, cured, and prepared to be sold as flower to medicinal and recreational dispensaries, but a portion of the crop will be distributed to processors and extractors.

It’s hard to determine precisely how much of this year’s harvest will be concentrated, extracted, or turned into edibles, but if consumer demand is any indication, the amount of fresh cannabis set aside for concentrates will continue to rise.

The Growing Demand for Concentrates

According to a report by Arcview Market Research & BDS Analytics, concentrates are now the fastest-growing product category in cannabis. The study analyzed the growth of flower, concentrates, and edibles and predicted that sales from concentrates would reach an estimated $8.4B in retail sales by 2022, closely approaching the $8.5B expected from flower sales.

The fastest growing and most popular way to consume concentrates is through vaping. The report by Arcview Market Research & BDS Analytics estimates that vape cartridge products will reach nearly $6.5 billion in sales by 2022, and comprise 80% of the total sales from concentrates. Experts are also predicting that it won’t be long before concentrates outpace flower sales.

What exactly is a concentrate?

Consumers looking for consumption methods other than traditional smoking have increased the demand for concentrates, but what exactly is a concentrate and how is it produced?

A concentrate is a product that’s been refined or processed from plant material to remove excess material and impurities. Concentrates allow processors to focus on specific and desired components in the plant material. It allows them to isolate cannabinoids like THC and CBD as well as the terpenes that give a particular strain its flavor and aroma profile. Simply put, concentrates enable manufacturers to manage purity, potency, taste profiles, and dosing.

Producing concentrates is a big business and leads to a variety of products, including popular extracts like the oils used in vape cartridges. But concentrates come in other forms and consistencies as well. In addition to oils, there are distillates, tinctures, shatter, wax, hash, rosin, dry sieve, and many others.

Extracts and Concentrates: What’s the Difference?

The main difference between concentrates and extracts is how they are processed. Concentrates that are produced using a solvent are known as extracts. Vaporized oils are extracts, so are distillates, tinctures, shatter, wax, and live resins.

There are some concentrates such as kief, dry shift, and hash that are created mechanically without the use of solvents. They often depend on moderate heat, mechanical pressure, and water or vegetable oils.

So, to recap, all extracts are concentrates, but not all concentrates are extracts.

Processing Cannabis into Extracts

Extractions are the heavy hitters of the concentrate world. Popular extracts, including the oils contained in vaporizer cartridges, are created using solvents such as butane, propane, ethanol or CO2 (supercritical carbon dioxide). To create oils and extracts, processors use basic scientific practices that have been employed for years by the botanical, chemical, and distilled spirits industries. This video can help you understand the fundamental science behind the process and how temperature plays a role.

The two main processing techniques you’ll want to master are:

- Extraction (which uses a solvent to separate the desired compound from the rest of the plant material).

- Distillation (which isolates, purifies, or refines the desired components you’ve extracted).

The conventional extraction methods used in cannabis rely on a solvent to draw out desired components such as CBD, THC, or terpenes. There are several solvents to choose from, and some work better than others.

Common Solvent Options for Cannabis Extraction

- Ethanol (EtOH) is considered the universal solvent. It’s a safe, effective, and classic option. It doesn’t require high pressure like supercritical CO2 or butane and produces a full spectrum concentrate, which allows other components in the plant to participate in the therapeutic experience, known as the entourage effect. Read more about this recommended solvent.

- Hydrocarbon solvents, including butane and propane, are compounds made of hydrogen and carbon. Butane and propane evaporate easily making solvent removal easy. While they are efficient, they do require careful handling and engineering protocols due to their highly flammable nature.

- Supercritical Carbon Dioxide (CO2) requires pressurizing the CO2 gas to a supercritical state that behaves like a liquid. This is done through high pressure. The pressurized CO2 passes through a chamber containing the cannabis. The reduction of pressure allows the CO2 to evaporate and leaves a solvent-free extract. While the extract is free of solvent, the pressurizing process has to be carefully engineered and monitored.

Post-Extraction Processing

Extraction is the first part of the process, and both winterization and distillation may be required to complete the workflow.

Winterization is used to remove unwanted fats/lipids and waxes from the extraction. This can be done by dissolving the extract in warm ethanol and cooling the solution to a temperature low enough to solidify and filter off the undesirable fats.

Distillation allows you to purify the concentrate by evaporating any remaining solvents. This is typically done using a rotary evaporator or vacuum distillation apparatus to reclaim any residual solvents and leave you with a solvent-free extract. Distillation methods include short path, fractional, and wiped or rolled film.

The Role of Temperature Control

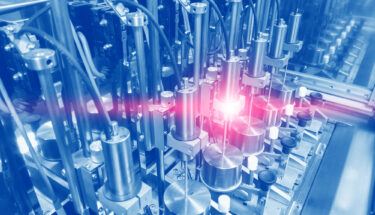

Regardless of the extraction and distillation processes you use, temperature control will play a vital role in each step. To create extractions like vape oil that are driving sales, you’ll need to power the processing equipment with ancillary temperature products such as:

- High temperature/ heating circulators

- Low-temperature circulators

- Chillers

Resources To Help you Gear Up for Croptober

If you’re ready to gear up for Croptober but still have questions about the equipment you need to regulate temperatures, here are some resources that can help.

Go here to explore the types of equipment you’ll need to regulate temperatures during the extraction, distillation, and evaporation processes. This site provides an overview of the equipment you’ll need to heat and cool rotary evaporators, closed-loop systems, extractions, distillations, decarboxylation, winterization, and other processes. You’ll find a list of the type of heating and cooling you’ll need for:

- Supercritical Carbon Dioxide (CO2) Extractions

- Ethanol Extractions

- Butane & Propane Extractions

- Processing Residues and Winterization

- Falling Film Evaporation

- Vacuum Distillation

- Short Path Distillation

- Wiped or Rolled Film Evaporation

- Decarboxylation

The resource contains some other cool information including the explainer video on the fundamentals of temperature control for cannabis processing, as well as a link to download our recently updated whitepaper “The Importance of Temperature Control in the Cannabis Workflow.” And, another bonus includes special Croptober discounts on select temperature control equipment.

Croptober Preparation for Concentrate Manufacturers

As Croptober gears up, it’s an excellent time to review the processes, safety protocols, and equipment you’ll need to make the most of the outdoor-grown harvest. With more and more cannabis flower users preferring indoor-grown buds for aesthetic reasons, it makes sun-grown cannabis the perfect complement to extraction processing.

If you need additional assistance preparing for the season, we can help. JULABO partners with the top processing consultants and equipment suppliers for the legal cannabis industry. Our equipment is used to help processors dial in the perfect temperatures to maximize yields, potency, and purity. We’d love to help you make this year’s Croptober your greenest one yet. For personal assistance with your Croptober temperature control equipment, contact us directly.

To learn more about the best tools and techniques to improve your cannabis product manufacturing, visit our Cannabis Resource Hub to access more information on ethanol extractions, the temperature control equipment you’ll need for processing cannabis, current promotional pricing, and our whitepaper/weedpaper, The Cannabis Workflow and the Importance of Temperature Control.

The information presented is solely intended for businesses engaged in the lawful cultivation, manufacturing, processing, and/or distribution of cannabis or hemp-based products in the US or Canada. JULABO USA’s products are to be used for lawful purposes only. Nothing contained in this post is intended to assist, condone, or promote any violation of any law. JULABO USA makes no representation regarding the legality of cannabis or hemp-based products under the laws applicable to you or your business.

To learn more about JULABO USA, visit us at julabo.us.