Protect & Cool Your Laser with a Recirculating Chiller

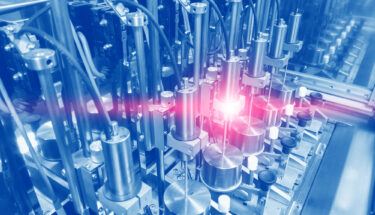

Since its invention in 1960 by Theodore Maiman, the laser has found many uses in modern life. Lasers come in various sizes, from the small consumer type that can fit in your pocket and function as a pointer to large-scale industrial lasers for metal cutting and defense applications. In addition, lasers have found various applications in electronic products, motor vehicles, medical procedures, and scientific investigations.

Like the one cats like to chase, small lasers can function well in ambient conditions. This is because the laser optics and power supply (often a battery) don’t produce much heat. However, larger, more powerful lasers amp up the heat generation and require cooling to maintain stability. These lasers produce more heat than can be removed by radiative or air cooling methods. Once the heat generation exceeds a few hundred watts, larger lasers require liquid cooling for proper operation.

Laser Cooling — Recirculating Chillers vs. Tap Water Cooling

Recirculating chillers offer many benefits for laser cooling, including consistent flow rates, pressures, and temperatures. It’s also a more cost-effective and environmentally-friendly method, as it doesn’t waste large volumes of water.

Tap water cooling has inherent flaws compared to using a recirculating chiller. With tap water cooling:

- Temperatures can fluctuate daily and seasonally.

- Pressure and flow rates change based on water demands within the facility or municipal water source.

- Many municipalities and regions restrict single-pass water usage.

- Water and sewage bills can increase dramatically, adding significantly to operating costs.

Recirculating chillers are a superior option for laser cooling.

- Chillers eliminate fluctuations in cooling capacities, flow, and pressure.

- The cost of the chiller is offset by the elimination of additional water/sewage fees and operational costs.

- The chiller provides the proper cooling capacities for the laser to produce a fine beam with maximum efficiency.

Reduce Problematic Laser Pulsations with a Recirculating Chiller

Recirculating chillers offer a variety of pump options. A laser cooling application needs to select a pump that eliminates flow pulsation. A cooling water pulsation can create a vibration effect, causing a less focused beam and thermal instability. Pumps to avoid include positive displacement versions like piston, diaphragm, or gear designs. Chillers with centrifugal pumps supply pulsation-free cooling liquid to the laser system.

Laser Cooling Solutions from JULABO USA

JULABO offers a range of F and FL model recirculating chillers with cooling capacities ranging from 250W to 20kW at 20°C. These recirculating chillers include environmentally friendly refrigerants with temperature stability of ±0.5˚C. FL chillers incorporate proportional cooling control, which adjusts the amount of cooling power based on the external load, reducing energy consumption and extending the compressor’s lifetime.

For assistance finding and sizing a recirculating chiller based on your laser, contact your local JULABO USA account manager. Your account manager will work directly with you to provide a personalized product recommendation that ensures you get the best chiller for your application and operational goals.