What pumps are used in laboratory temperature control units, and how do they differ?

Temperature control units (TCUs) rely on integrated pumps to circulate heat transfer fluids through a closed-loop pathway to an external application. Discover the differences between centrifugal pumps, positive displacement pumps, and turbine pumps and the pros and cons of each.

TCUs use several pump designs; we’ll examine three primary pump classes and how each affects fluid flow. Maintaining efficient fluid flow through an application is vital to an efficient process. The required flow rates and pressure vary depending on the application variables.

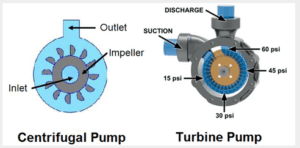

Centrifugal Pumps

Centrifugal pumps incorporate an enclosed plate-mounted curved vane rotated by a motor. A low-pressure area draws fluid into the center of the pump as the vanes rotate. The liquid accelerates across the curved vanes and exits the pump outlet yielding a pressure/flow rate dependent upon the pump design and speed. Centrifugal pumps do not self-prime; therefore TCUs typically install them in the bath tank or in line with the TCU internal bath fluid. Centrifugal pump limits on fluid viscosity generally range from 0.1 to 200 cP. Centrifugal pump efficiency declines as viscosity increases. Centrifugal pumps provide a constant fluid flow rate at a particular pressure, do not require in-line bath fluid filtration, and can withstand deadheading without damage. Centrifugal pumps have an inverse relationship between pressure and flow, with maximum pressure at a low flow rate and the highest flow rate at minimum pressure.

Videos you might like to explore:

JULABO TCUs incorporate a variety of pressure and pressure/suction centrifugal pumps. JULABO USA includes the performance data for the pump on each product’s datasheet. Systems with a pressure/suction pump have lower flow/pressure capability on the suction side.

Red line = pressure side

Blue line = suction side

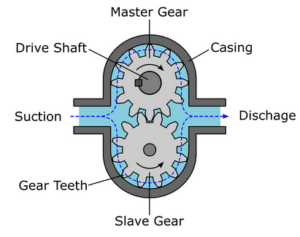

Positive Displacement Pumps

Positive displacement (PD) pumps function, as the name implies, by mechanically displacing fluid to provide flow/pressure. The pump components draw in a fluid and physically force it through the outlet. The design of the internal PD components can vary between gears, lobes, vanes, screws, or pistons. Given the mechanical nature of the pumping mechanism, PD pumps provide a steady flow rate at a set RPM across a range of pressure. In other words, a PD pump does not have a pressure/flow rate dependence like a centrifugal pump.

PD pumps cannot operate under closed valve or deadhead conditions as the pressure continues to build, resulting in potential burst tubing and/or damage to the PD pump.

Given the tight mechanical tolerances designed into a PD pump, they do not tolerate particulates. If necessary, based on the application, the installation of an in-line fluid filter alleviates this concern.

In the JULABO portfolio, larger PRESTO TCUs such as the W56x, W91x, and W92x (and variants) incorporate a PD gear pump. A gear pump consists of two gears, with the master gear driven by a motor.

Comparison of Centrifugal and Positive Displacement Pumps

Centrifugal and PD pumps comprise most pump styles installed in TCUs. Here is a comparison of the two:

| Property | Centrifugal Pump | Positive Displacement Pump |

| Viscosity Range | Excellent for low viscosity fluids. Efficiency decreases with increasing viscosity (max = 200 cP) | Efficiency increases with increasing viscosity |

| Pressure Tolerance | Flow rate changes with varying pressure | Flow rate constant with varying pressure |

| Efficiency drops at high and low pressures | Increased efficiency with higher pressure | |

| Priming | Required | Self-priming |

| Flow (at constant pressure) | Constant | Pulsating |

Turbine Pumps

Some manufacturers install turbine pumps in TCUs. Turbine pumps represent a hybrid having curve vanes (thus the turbine) like a centrifugal pump with the tight tolerances of a positive displacement pump. The pumping mechanism consists of multiple rows of small diameter vanes, increasing the fluid flow rate and pressure as it passes through the pump. Turbine pumps provide the high-pressure capability of a positive displacement pump with the flexible operation of a centrifugal pump. Due to the tight tolerances, turbine pumps do not tolerate particulates; thus a TCU will have an internal filter to protect the pump.

Comparison of centrifugal and turbine pumps:

Credit: Water Baths Blog

Conclusion

Pumps play a critical role in liquid temperature control applications. Applications vary considerably, making flow rate and fluid pressure an essential variable for successful liquid temperature control. The nuances and characteristics of pump options can be confusing. Don’t hesitate to contact our team to discuss your fluid pumping and liquid temperature control requirements. Our experts will ensure you get the appropriate TCU to optimize your application.