|

|

|

|

Please select your desired JULABO USA destination below.

*Select My Account to make a purchase or view past order history. If you are a distributor or OEM, please select Partner Portal to access JULABO resources."*" indicates required fields

JULABO PRESTO® Highly Dynamic Temperature Control Systems for highly precise temperature control of external applications. Systems offer rapid heating and cooling rates for fast compensation of external events. The hydraulically sealed heat exchanger design afford a wide working temperature range without changing fluids. All units feature a 5.7″ industrial color TFT touch screen interface for unit operation, external integration and programming.

These instruments cover a working temperature range of -30 to +250°C to -92 to 250 °C. Up to three user levels with password managment enable safe, repeatable operation. Systems incorporate USB (host and device), Ethernet, SD-card slot, RS232 port, stand-by input and Pt100 external temperature sensor port.

The graphite bearing centrifugal pressure pump is lubricated by the bath fluid. All models (except for A30) can operate under pressure control to safeguard pressure sensitive applications (such as jacketed glass reactors).

Air and water-cooled versions available. Use only with approved JULABO fluids. Systems can operate with silicone fluids (Thermal P60 and Thermal P90) and HFEs (Fluorinert® and Galden®). Single stage PRESTO systems can operate with 1:1 ethylene glycol/water mixtures from -30 to +90 °C. Additional accessories available.

|

|

|

|

Learn how to perform an ATC, or Absolute Temperature Calibration, on your PRESTO unit.

In this video Electronics Service Team Leader, Nelson Hill, will discuss the various analog interface options that some of our products have as either optional or standard, including stand-by input (STAND-BY), alarm output (ALARM), and programmer input/temperature recorder output (REG+E-PROG).

In this video Electronics Service Team Leader, Nelson Hill, will discuss the various analog interface options that apply to PRESTO units.

Learn how to connect your PRESTO to the CERhost program, which duplicates the front screen controls on your computer at your desk.

Learn how to connect your PRESTO or MAGIO circulator to EasyTEMP using the Ethernet connection.

In this video, Felix Silverio, Electronics Service Technician, will demonstrate how to manipulate CoSpeed on a PRESTO.

In this video you will learn how to record data from your PRESTO to a USB stick or an SD card. . This allows you to record data from the unit’s operation without having to connect it to a computer.

Learn how to download black box data from the PRESTO product line. Make sure you have a USB stick no more than 2 GB large, formatted in FAT32 and make sure there are no other files on the USB stick.

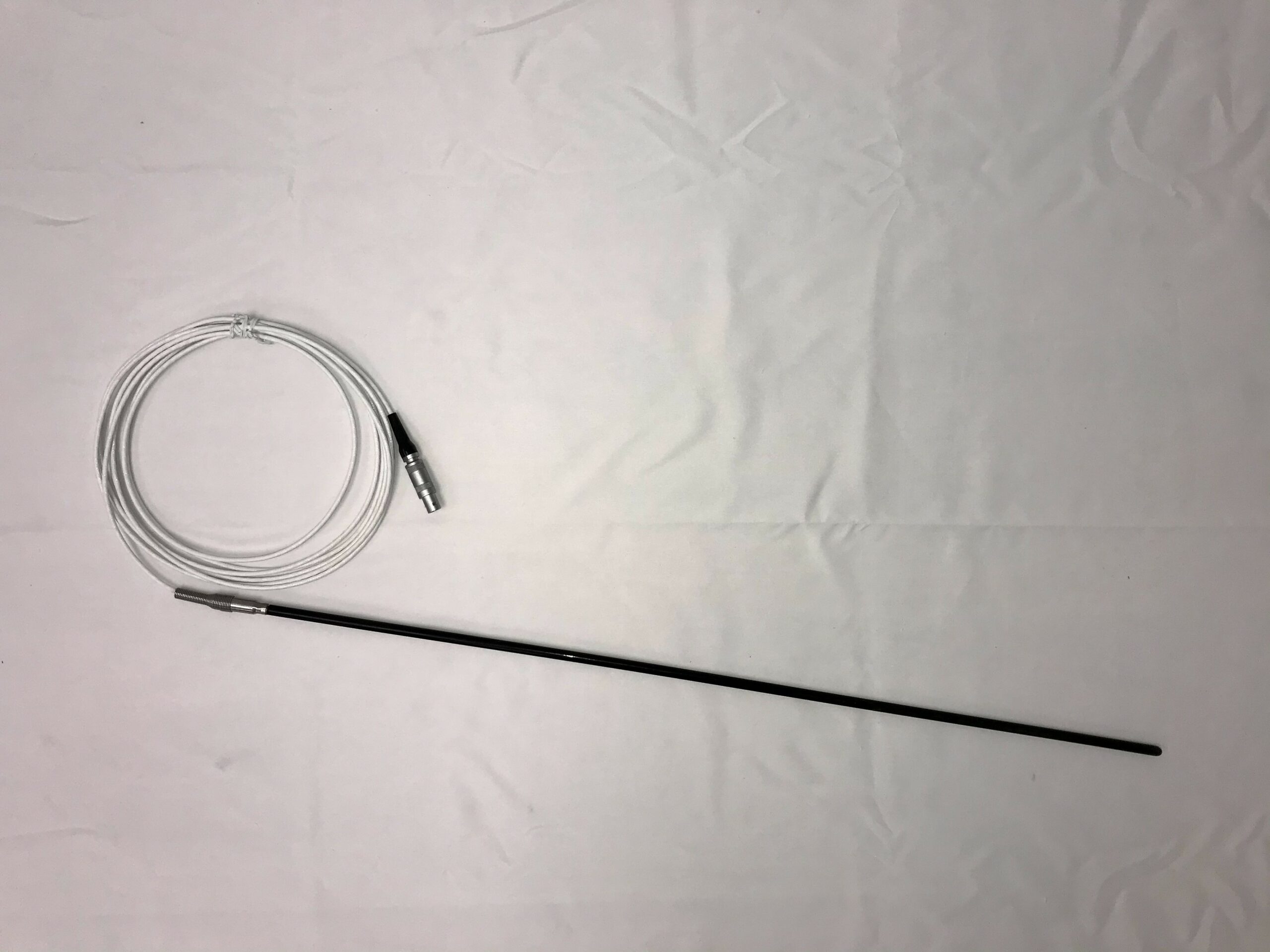

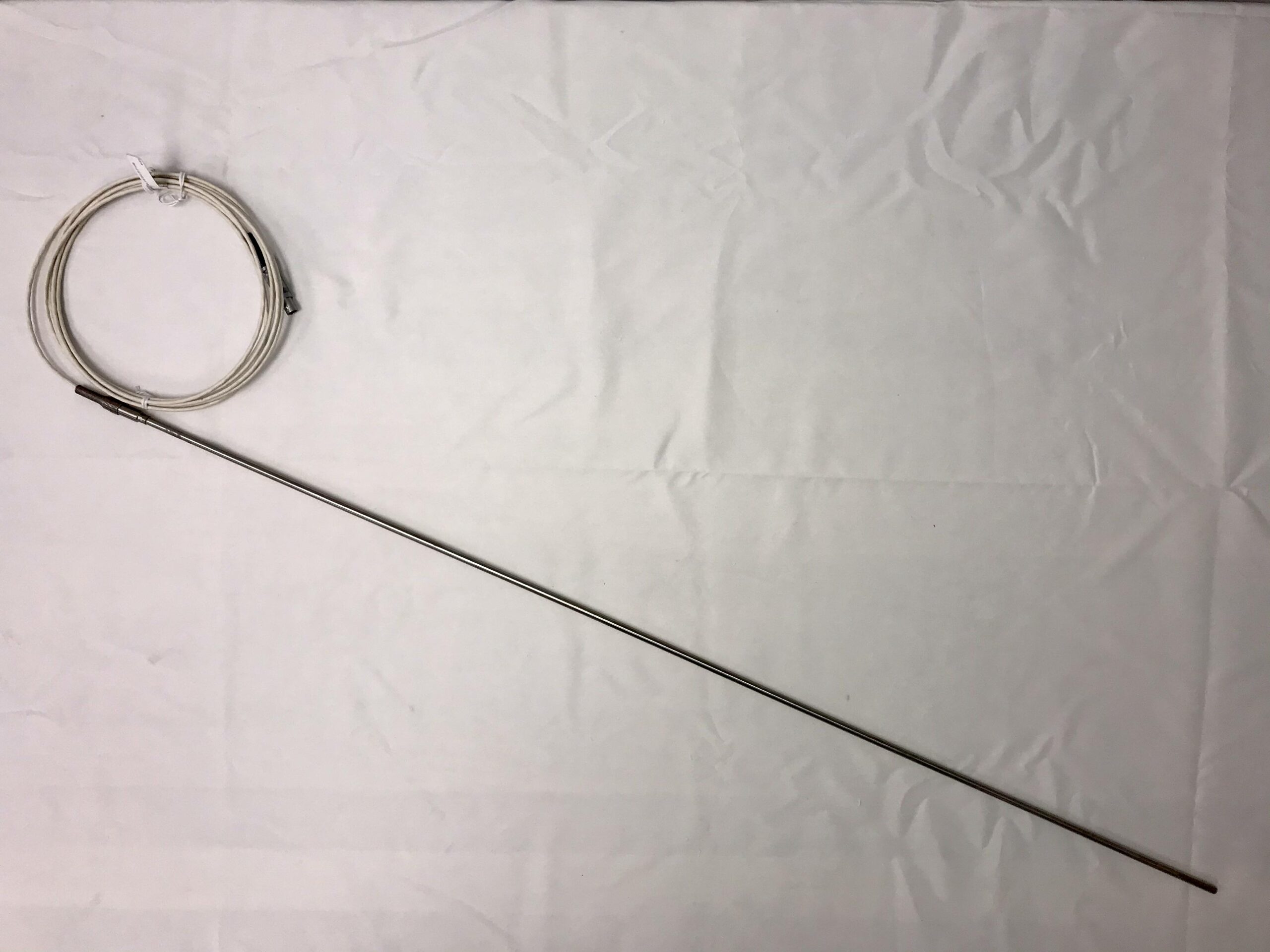

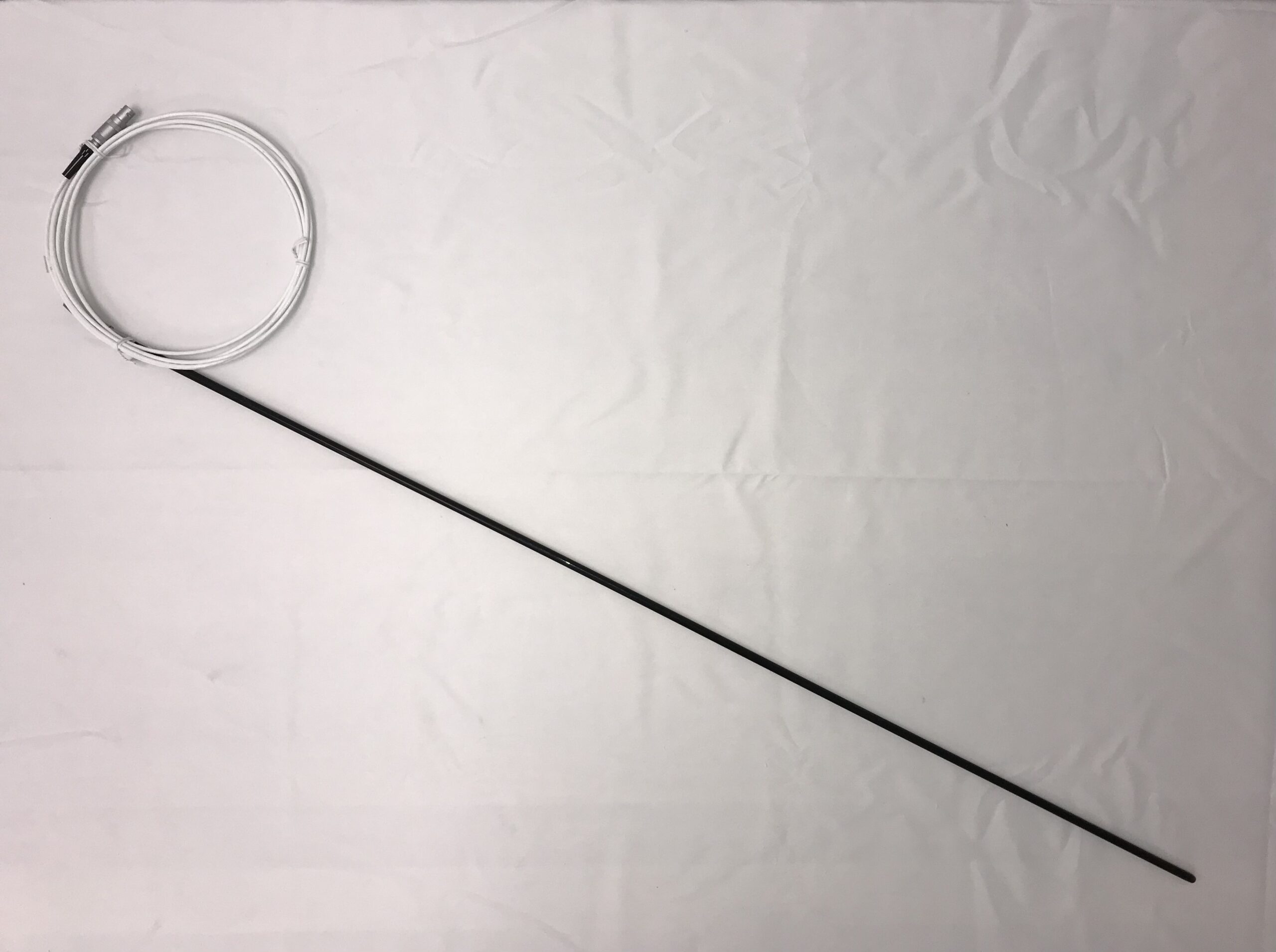

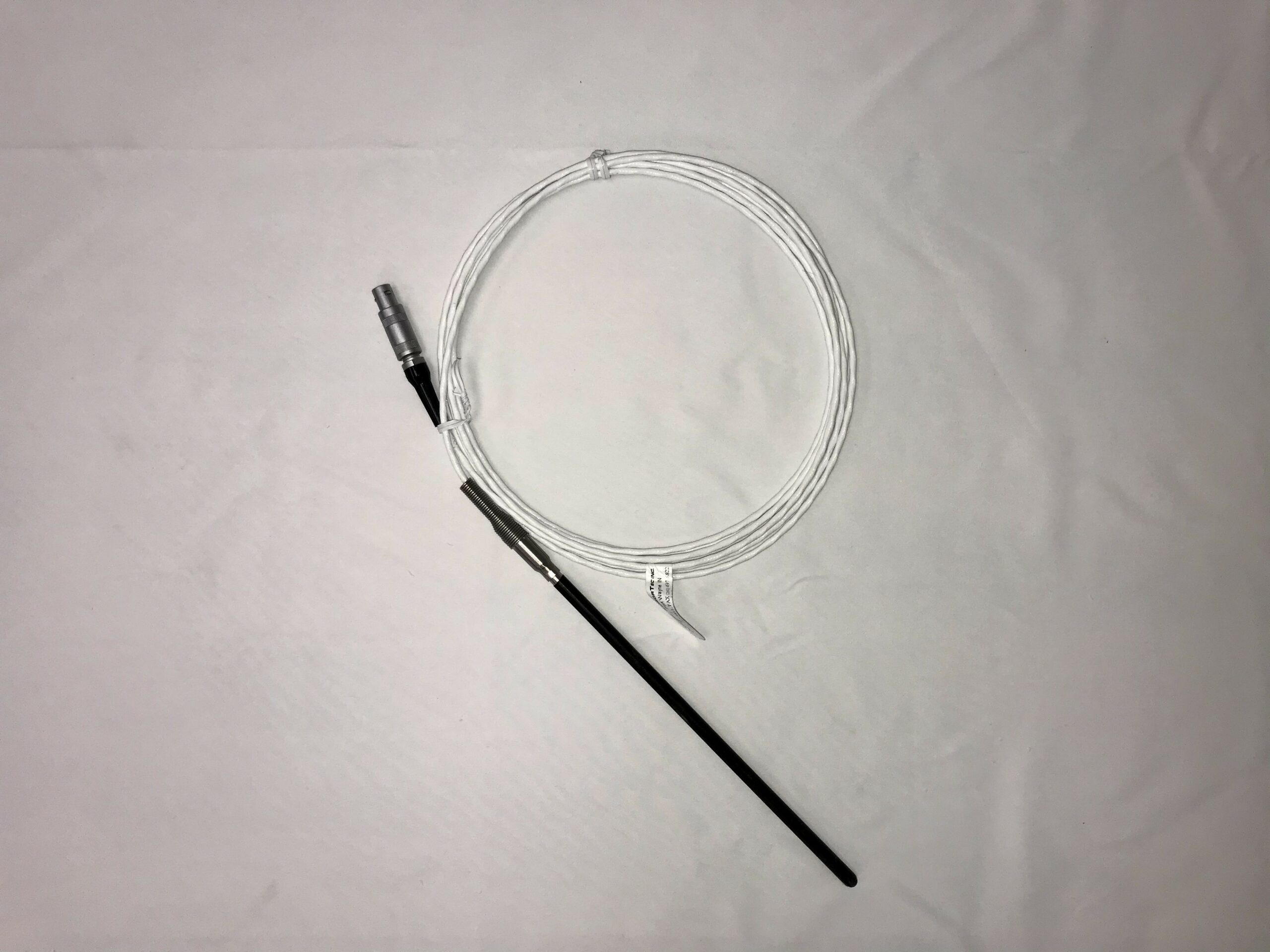

Learn how to set up your unit for external Pt 100 control, using a PRESTO product.

In this video, Nelson Hill will walk you through how to install a Flow Control Solution on your PRESTO unit.

In this video, Nelson Hill introduces you to our PRESTO Flow Control Solutions, including why you would need a flow controller for your application and which PRESTO units are compatible.

In this video, Nelson Hill will show you how to operate your Flow Control Solution, including the menu features on the PRESTO that are displayed when a flow controller is installed.

Learn how to fill your PRESTO temperature control unit with bath fluid.

In this video, Nelson Hill explains how to use the internal programmer on a PRESTO temperature control system.

Check out our PRESTO product line. It’s our most advanced temperature control system. Its closed bath system design and cold oil overlay technology allow you to do things you can’t do with traditional open bath systems.

In this video, Sr. Product Manager Mark Diener, talks about the importance of external temperature control using Pt100 sensor and monitoring the temperature in your glass reactor.

Welcome to JULABO. Today, I’d like to talk about the PRESTO A80 and A80t. They look identical and they both have the same temperature range from -80°C to 250°C. They both utilize the cold oil overlay, which enables a very broad temperature range with one fluid. If you’re doing cold temperature applications for cannabis workflow, the A80 will work well for you. It only requires a 20-amp, single-phase 208-to-200-volt outlet. So at -40°C, both models have 1.1kW of cooling power at -40°C and 650 watts of cooling power at -60°C. For cold temperature applications in the cannabis or hemp workflow, these are great hydrocarbon extraction cooling, crystallization, winterization, and anything that might need 1.1kW at -40°C. Also for ethanol extraction, it can be used for smaller-scale centrifuges, for example. On the high end, the A80t offers 2.8kW of heating power. So, you could use the PRESTO A80t for application in vessels up to 20-50 liters, if you will, for decarb. So, in that case, the PRESTO A80t could be used on a reaction vessel for decarb and then also for winterization before that. And, later on, then, you could do crystallization for example if you’re trying to make diamonds or other types of solid, high-purity isolate products. So, if you have any more questions, please click the link to learn more about the PRESTO A80 and A80t products. Thank you.

Watch this video to learn the fill procedure with the PRESTO unit connected to a glass reactor.

Watch this video to learn PRESTO pressure limit settings, especially if you’re using a jacketed glass reactor.

Learn how to set your PRESTO to be controlled using RS232, USB, or the Ethernet interface.

In this video, Felix Silverio, Electronics Service Technician, will demonstrate how to perform the selftune function with an external application on a PRESTO.

In this video, Felix Silverio, Electronics Service Technician, will demonstrate how to perform the selftune function with an internal application on a PRESTO.

In this video Senior Customer Service Support Technician, Mary Pop, will demonstrate how to update the configuration on our PRESTO temperature control systems.

In this video, Sr. Product Manager Mark Diener discusses key industries that use PRESTO product lines. Mark talks about engineers and chemists in pharmaceuticals, automotive, aerospace, and cannabis markets and the type of applications that need a PRESTO in their lab.

In this video, Sr. Product Manager Mark Diener, discusses why the PRESTO product line is ideal for temperature control applications, specifically because of the cold-oil overlay technology.